Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

+44 (0)1302 831555

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and improved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

statement

Environmental Policy

Opening Hours

Mon - Fri 08:00 - 17:00

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

NORTHERN PRECISION LTD

Specialist Fasteners

for Sheet Metal

+44 (0) 1302 836010

+44 (0) 1302 831555

Tel:

Fax:

sales@npfasteners.com

Quality

Service

Reliability

Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Cage Nuts

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

SERVICES & SUPPORT

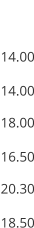

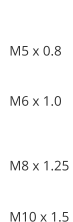

Pias Nuts Type KP

Pias Nuts Type HN

Pias Nuts Type PNC

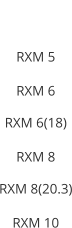

Rivtex Nuts Type RXM

Rivtex Studs Type RXS

Strux Studs Type SX

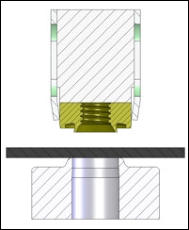

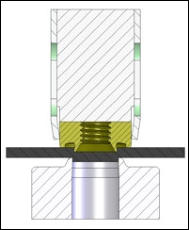

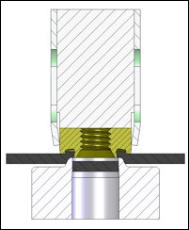

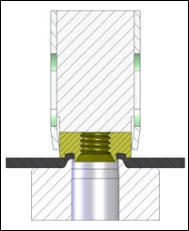

Installation Method & Performance

1

2

3

4

Material & Finish

Unplated Steel (X)

Electro Zinc/Clear Plated Steel (ZI)

Electro Zinc/Nickel Plated Steel (ZN)

Electro Zinc/Heavy Plated Steel (ZI96)

Thread tolerance on unplated parts 6G

Thread tolerance on plated parts 6H

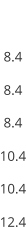

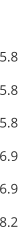

Part Number Examples

Part number is made up as follows:

(Part code)-(Material/Finish code)

For example:

RXM-6-ZI (RXM Nut-M6-suitable for 0.75 to 2.00mm panel

thickness-electro zinc/clear plated steel)

RXM-8(20.3)-ZN (RXM Nut-M8(larger OD)-suitable for 0.75 to

2.00mm panel thickness-electro zinc/nickel plated steel)

Downloadable Data Sheet

Back

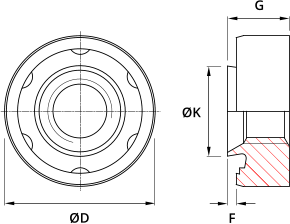

Dimensional

Info

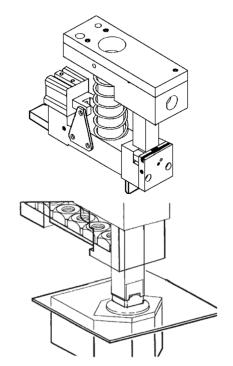

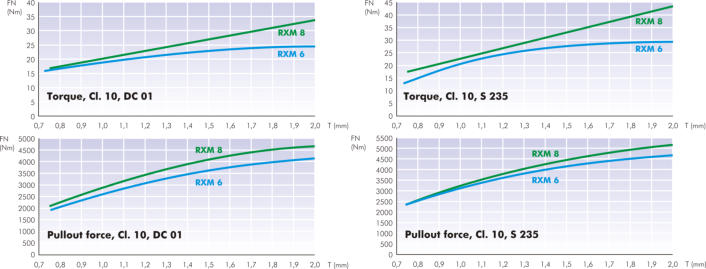

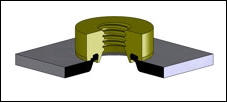

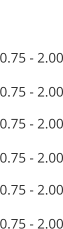

RIVTEX®-RXM self-piercing nuts are available in sizes M5 to M10 in property class 10. Each thread size is suitable for

installation in panel thicknesses ranging from 0.75mm to 2.0mm. The Rivtex® installation tooling system is required

to install Rivtex® nuts.

Available in metric thread sizes in strength class 10 steel, they can be supplied as unplated or with a range of

electro plated zinc finishes including zinc/clear, zinc/nickel and zinc/thick film passivated.

Benefits of Rivtex® RXM Nuts include:

•

Self piercing so no need to pre-punch the hole, meaning one less process is required and there is no potential

for misalignment between hole and nut

•

Reliable, flexible installation process

•

One nut can be installed in various panel thicknesses from 0.75 to 2.00mm

•

Excellent torque-out and push-out performance

•

Various feeding options available

•

Can be specified with a self-locking thread

Rivtex® is a trademark of Rt Holdings Iii Wg (Us), Lp SCS Luxembourg.

RIVTEX® SELF PIERCING

RXM NUTS