Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

+44 (0)1302 831555

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and improved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

statement

Environmental Policy

Opening Hours

Mon - Fri 08:00 - 17:00

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

NORTHERN PRECISION LTD

Specialist Fasteners

for Sheet Metal

+44 (0) 1302 836010

+44 (0) 1302 831555

Tel:

Fax:

sales@npfasteners.com

Quality

Service

Reliability

Installation Method & Performance

Performance

Do not remove any extra material or

chamfer the hole as this could result in

improper installation or reduced

performance.

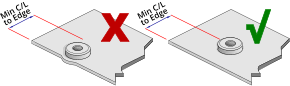

Ensure that attention is paid to the

minimum hole centreline to edge

dimension for each fastener. Installing

too close to an edge or bend could result

in improper installation or reduced

performance. Minimum centreline to

edge dimensions shown for each

fastener apply to one edge only. If this

distance is applied on multiple sides

there will be significant panel distortion

unless the panel edges are supported

during installation.

First prepare the specified hole in the panel.

Place the fastener in the panel and then locate in the anvil.

Ensuring the panel is held level, apply a parallel squeezing force

until the head of the fastener is seated against the panel. Do

not over squeeze the fastener into the panel as this will result in

panel deformation or damage. Broaching studs do not install

flush (refer to A dimension).

When installing broaching studs, please pay attention to the

minimum hole centreline to edge limitations.

E

±0.08

4.10

3.10

Thread

code

M4

M3

Anvil Dimensions

All performance figures are averages obtained over a range of installations and should be used for guidance only. Panel material, hole

preparation, installation tooling and method can affect part performance. We always recommend that you carry out your own tests in the

actual application. Please call our sales team and we will be happy to provide you with samples as well as offering technical assistance.

E

L dimension min.

5.10

M5

Installation

(kN)

1.7

1.8

1.9

Push-out

(N)

280

350

400

Torque-out

(Nm)

0.8

1.8

1.9

Test Sheet Material

1.6mm FR4 Epoxy Laminate

1.6mm FR4 Epoxy Laminate

1.6mm FR4 Epoxy Laminate

Thread

code

M3

M4

M5

Max. nut

tightening

torque (Nm)

0.45

1.6

2.1

Material & Finish

Electro Tin Plated Phosphor

Bronze (ET)

Maximum recommended

panel hardness: 55HRB

Part Number Examples

Part number is made up as follows:

(Type)-(Thread code)-(Length)-(Material/Finish code)

For example:

CBFH-M4-10-ET (Broaching Stud-M4-10mm long-electro tin plated phosphor

bronze)

Downloadable Data Sheet

Back

Dimensional

Thread

size

M3 x 0.5

M4 x 0.7

Hole size

+0.08

3.00

4.20

B

Max.

1.65

1.65

A

±0.13

0.51

0.51

C

Max.(1)

2.30

2.30

Min. panel

thickness

1.53

1.53

D

±0.25

4.58

5.74

M5 x 0.8

5.00

1.65

Min. CL to

edge of

panel

3.80

5.10

5.30

0.51

2.30

1.53

6.60

Max. hole

in attached

parts

3.70

4.80

5.80

(1) Threads are gaugeable to within 2 pitches of this dimension.

Info

Broaching studs provide strong male threads in non-ductile materials such as printed circuit board, polycarbonate,

acrylic, glass epoxy and resin laminate components as well as ductile panels with a maximum hardness of 55HRB.

Featuring an axially knurled ring, the serrations are designed to cut into the panel material as it is installed, resulting

in an interference fit that offers good torque-to-turn resistance and push-out performance.

Installation is simple, prepare the specified hole and using a flat punch and appropriate anvil, apply a parallel

squeezing force to press the part into the hole. When installing in printed circuit board, broaching studs are suitable

for use in non-plated holes only.

Available from stock in various metric thread sizes and lengths in electro tin plated phosphor bronze, broaching

studs are suitable for installation in panels with a maximum hardness of 55HRB.

BROACHING

STUDS

Available Lengths (L) ±0.25

6

8

10

12

15

18

20

Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Cage Nuts

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

SERVICES & SUPPORT