Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and improved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

statement

Environmental Policy

Opening Hours

Mon - Fri 08:00 - 17:00

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Spring Steel Fasteners

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

Keep-Nut Guide

Keep-Nut Flush

Keep-Nut Flanged

Keep-Nut Stud

Master-Plate Guide

Master-Plate Stud

Master-Plate Blind Standoff

Master-Plate Through

Standoff

Master-Plate Through Nut

Deform-Nut Guide

Deform-Nut Type TC

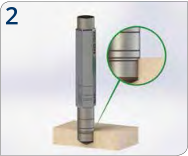

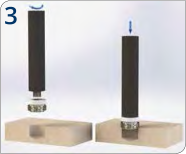

Installation Method & Performance

Prepare hole in base material

to correct specification.

Verify hole diameter using

Go/No-Go gauge. Check hole

depth against reference line

on Go side of gauge.

To ensure correct installation

it is recommended that a

threaded mandrel is used.

Fully screw on the insert and

drive into the hole.

Unscrew the mandrel and the

insert is installed and ready

for use.

Example assembly

Material

Granite 20mm

Marble 20mm

Travertine 20mm

Fibre cement (high density) 12mm

Fibre cement (high density) 10mm

Fibre cement (high density) 8mm

HPL 12mm

HPL 10mm

HPL 8mm

Corian 12mm

Corian 10mm

Agglomerate stone 15mm

Tempered glass 5mm

Keep-Nut

Type

KN4 M6 H8.5

KN4 M6 H8.5

KN4 M6 H8.5

KN4 M6 H8.5

KN4 M6 H8.5

KN2 M6 H6

KN4 M6 H8.5

KN4 M6 H8.5

KN2 M6 H6

KN4 M6 H8.5

KN2 M6 H6

KN4 M6 H8.5

KN1 M4 H5

Average pull-out

load on a single

insert (Kg)*

490

385

225

275

239

125

541

611

270

484

295

305

75

Comparison of results from tests carried out on a range of materials.

* Tests were carried out under laboratory conditions. Pull-out figures are

indicative only and are offered for guidance purposes. It is recommended

that you undertake your own tests in the actual application panel material.

Advantages

•

Simple hole preparation

•

Quick installation

•

No need for resins or adhesives

•

Radial force is produced only while

the insert is under tensile load.

The crowns spread the load into

the parent material, allowing large

loads to be carried

•

Thread stops before end of insert,

avoiding extraction as a result of

the use of an excessively long bolt

Material & Finish

Bush: Stainless Steel

Crown: Stainless Steel

Body: Plastic

Part Number Examples

Part number is made up as follows:

(Type code) (Thread code) (Height code)

For example:

KNF1 M4 H5 (Keep-Nut Flanged 1 crown M4 5mm overall height)

KNF2 M5 H6 (Keep-Nut Flanged 4 crowns M6 8.5mm overall height)

KNF4 M6 H8.5 (Keep-Nut Flanged 4 crowns M6 8.5mm overall height)

Downloadable Data Sheet

Back

Dimensional

M4

KNF1 M* H5

M5

KNF2 M* H6

M6

M5

7.0

7.5

M4

5.5

4.5

KNF4 M* H8.5

M6

M5

10.0

M4

7.5

M6

Info

Keep-Nut® is a press-in threaded insert that utilises a mechanical anchoring feature, to provide permanent threads

in panels made of marble, granite or other stones, as well as composites, carbon, Corian®, HPL, glass and others

solid surface materials.

Keep-Nut is manufactured in stainless steel and consists of a threaded bush, a set of toothed spring washers

(crowns), and a plastic ring holding the parts together. Available in different lengths, with or without flange, to fit

several different panel thicknesses, Keep-Nut can be installed quickly since the user simply needs to drill the

material with the correct hole diameter and press-in the insert. Keep-Nut can also be customised with different

versions and sizes, to meet specific customer requirements.

The Keep-Nut insert is specifically developed to fasten ventilated façades, wall-coverings, décor and interiors,

furniture, kitchen and sanitary elements, as well as a variety of other applications.

Keep-Nut inserts have several advantages compared to other fasteners for stone and solid materials. The

preparation needed is just a cylindrical hole – an undercut hole is not required – which means that standard tools

can be used. In addition, assembly by pressure is quick and easy and does not require use of any additional resins

or adhesives. Keep-Nut inserts can be used for hidden assemblies without any protruding parts, facilitating the

handling and installation of a variety of materials.

In use, the crowns are engaged by axial force, acting radially against the hole wall, effectively permanently locking

the insert in place. In addition, the internal thread does not run completely through the bush, which prevents

extraction as a result of the use of an excessively long screw.

Keep-Nut is a trademark of SPECIALINSERT S.r.l., Corian is a trademark of E. I. du Pont de Nemours and Company.

(Type) (Thread)

(Height Code)

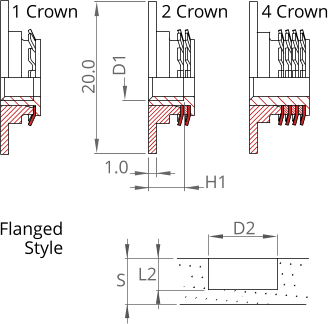

D1

Thread

S Min.

Thickness**

H1 Thread

Depth

D2

Hole Ø

±0.2

12

12

12

4.5

5.5

8.0

L2 Hole

Depth

+1.0

No. of

Crowns

1

2

4

Installation

Force (kN)*

0.2

0.4

1.0

Pull-Out

Force (kN)*

0.5

1.7

2.9

*Figures are indicative only and are offered for guidance purposes. ** Minimum material thickness is related to

parent material characteristics. It is recommended that you undertake your own tests in the actual application panel

material.

TYPE KNF

KEEP-NUT®

FLANGED