Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and improved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

statement

Environmental Policy

Opening Hours

Mon - Fri 08:00 - 17:00

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Spring Steel Fasteners

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

Keep-Nut Guide

Keep-Nut Flush

Keep-Nut Flanged

Keep-Nut Stud

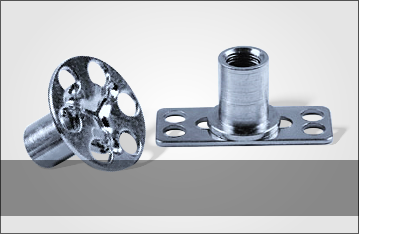

Master-Plate Guide

Master-Plate Stud

Master-Plate Blind Standoff

Master-Plate Through

Standoff

Master-Plate Through Nut

Deform-Nut Guide

Deform-Nut Type TC

Installation Method

Material & Finish

Steel Electro Zinc (ZI)

316 Stainless Steel (316)

Part Number Examples

Part number is made up as follows:

(Type code) (Base code) (Thread code) (L Length) (Material code)

For example:

BRC T2000 M5 10 ZI (Master-Plate Blind Standoff) (20mm Ø round base plate)

(M5 thread) (10mm standoff length) (zinc plated steel)

30

25

22

20

16

15

14

12

10

6

5

Part Code

Type / Base / Thread /

Length / Material

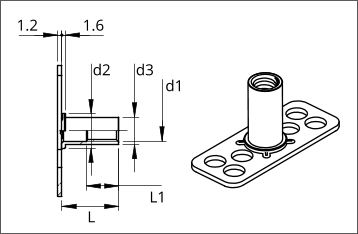

d1

Thread

d2

d3

BRC Q3232 M4 -- --

Ø

Holes

OD

BRC T1900 M4 -- --

BRC T2000 M4 -- --

BRC T2300 M4 -- --

BRC T3800 M4 -- --

BRC R3815 M4 -- --

M4

12.1

8.5

L Standoff Length

BRC Q3232 M5 -- --

BRC T1900 M5 -- --

BRC T2000 M5 -- --

BRC T2300 M5 -- --

BRC T3800 M5 -- --

BRC R3815 M5 -- --

M5

13.1

9.7

BRC Q3232 M6 -- --

BRC T1900 M6 -- --

BRC T2000 M6 -- --

BRC T2300 M6 -- --

BRC T3800 M6 -- --

BRC R3815 M6 -- --

M6

13.1

9.7

BRC Q3232 M8 -- --

BRC T1900 M8 -- --

BRC T2000 M8 -- --

BRC T2300 M8 -- --

BRC T3800 M8 -- --

BRC R3815 M8 -- --

M8

15.1

11.2

Standard

Special order

5

5

4

5

5

5

5

5

4

5

5

5

5

5

4

5

5

5

5

5

4

5

5

5

BRC Q3232 M10 -- --

BRC T1900 M10 -- --

BRC T2000 M10 -- --

BRC T2300 M10 -- --

BRC T3800 M10 -- --

BRC R3815 M10 -- --

M10

16.1

12.8

5

5

4

5

5

5

L1

Dimensional

Info

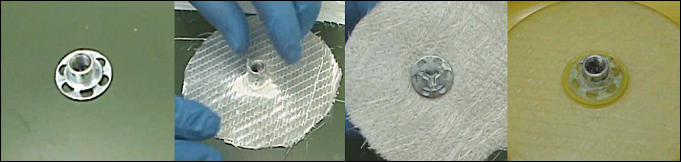

Master-Plate® bonding fasteners are available in a combination of base plate styles, in stud, standoff and nut

configurations.

Master-Plate is a cost effective, secure and reliable method of integrating male or female threads into composite,

fibreglass, laminate and carbon fibre applications.

Suitable for surface bonding using adhesive or embedding during the forming process, Master-Plate is ideal for

composites, fibreglass, carbon fibre, moulding compounds, plastics, laminated timber, stone etc.

Available in standard sizes, in thread sizes M4 - M8 for studs and M4 - M10 for standoffs and nuts, in zinc plated

steel and 316 stainless steel.

Custom base plate, fastener type, thread / body lengths can be produced to order.

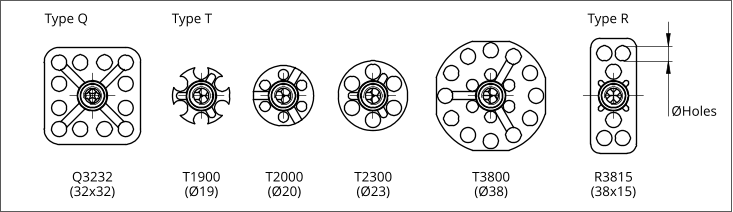

Base plate options

Adhesive type

Composites

Plastic

Wood

Metal

Natural

Stone

Conglomerates

Glass

PLEXUS MA300

L

OCTITE 9466

L

OCTITE 3425

Commonly used bonding adhesives and materials compatibility

Recommended

Reasonable

Not suitable

Please refer to adhesive manufacturer specifications for guidance.

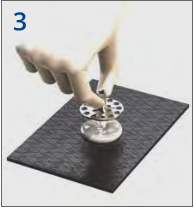

Prepare the panel surface by

cleaning thoroughly with IPA.

Ensuring the adhesive is fully

mixed, dispense sufficient

adhesive for the application.

Locate the Master-Plate

fastener over the adhesive.

Firmly press the Master-Plate

fastener into the adhesive until

adhesive flows through the

holes in the base plate.

Following the adhesive

manufacturers instructions,

allow sufficient curing time.

Once the adhesive is fully

cured, the Master-Plate

fastener is ready for use.

Alternatively Master-Plate fasteners can be embedded directly during the composite moulding process.

TYPE BRC

MASTER-PLATE®

BLIND STANDOFF