Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

+44 (0)1302 831555

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and improved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

statement

Environmental Policy

Opening Hours

Mon - Fri 08:00 - 17:00

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

NORTHERN PRECISION LTD

Specialist Fasteners

for Sheet Metal

+44 (0) 1302 836010

+44 (0) 1302 831555

Tel:

Fax:

sales@npfasteners.com

Quality

Service

Reliability

Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Cage Nuts

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

SERVICES & SUPPORT

Capacitor Discharge Weld

Studs & Pins

Capacitor Discharge Weld

Standoffs

Capacitor Discharge Earth

Tags

Projection Weld Bolts & Pins

Hexagon Weld Nuts

Square Weld Nuts

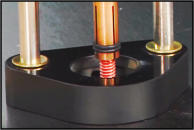

Weld Gun

Stud

Base Panel

Stud in place with

Initial pressure

provided by gun

on base panel.

Insert stud in

gun and position

on panel

Press

trigger

Welding

cycle

Release

Stud is now

welded in place

Stored energy is

discharged as a

high current pulse.

The high current

melts the pip on

the head and

produces an arc.

Return spring

pressure presses

the stud into the

molten surface

and fuses the

base of the stud

with the base

panel.

Perform your

preferred tests to

confirm correct

weld formation

and ensure stud

meets required

performance

criteria.

~0.04

seconds

1

2

3

4

Weldability cross reference

Base Panel Material

CD Weld Stud Material

Mild Steel

Stainless Steel

Aluminium

Brass

Low Carbon Mild Steel

Steel up to 0.6% carbon

Austenitic Stainless Steel

Zinc coated Steel

Electro Galvanised Steel

Hot Rolled Steel

Aluminium Alloy

Pure Aluminium

Lead Free Brass

Leaded Brass

Lead Free Copper

Good

Fair

Good

Fair

Fair

Fair

Not Weldable

Not Weldable

Good

Not Weldable

Fair

Good

Good

Good

Fair

Fair

Fair

Not Weldable

Not Weldable

Fair

Not Weldable

Fair

Not Weldable

Not Weldable

Not Weldable

Not Weldable

Not Weldable

Not Weldable

Good

Good

Not Weldable

Not Weldable

Not Weldable

Good

Good

Fair

Good

Good

Fair

Not Weldable

Not Weldable

Good

Not Weldable

Good

Material & Finish

Copper Coated Steel (CP)

Stainless Steel (A2)

Aluminium (AL)

Brass (BR)

Part Number Examples

Part number is made up as follows:

(Type)-(Thread/Dia.)-(Length)-(Material/Finish code)

For example:

WS-M4-10-CP (CD Weld Stud-M4-10mm long-copper coated steel)

WS-6MM-15-A2 (CD Weld Pin-6mm Diameter-15mm long-stainless steel)

Downloadable Data Sheet

Back

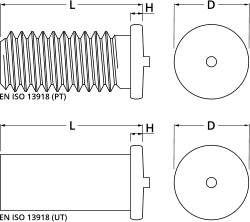

Dimensional

Thread Size

Pin Dia. ±0.1

M3 x 0.5

3MM

M4 x 0.7

4MM

M5 x 0.8

5MM

M6 x 1.0

6MM

M8 x 1.25

8MM

M10 x 1.5

D

4.5

5.5

6.5

7.5

9.0

10.5

H

0.7 - 1.4

0.7 - 1.4

0.8 - 1.4

0.8 - 1.4

0.8 - 1.4

0.8 - 1.6

L ±0.6

6

6

6

-

-

-

8

8

8

8

-

-

10

10

10

10

10

-

12

12

12

12

12

12

15

15

15

15

15

15

20

20

20

20

20

20

25

25

25

25

25

25

30

30

30

30

30

30

35

35

35

35

35

35

40

40

40

40

40

40

45

45

45

45

45

45

-

50

50

50

50

50

-

-

55

55

55

55

-

-

-

60

60

60

Preferred lengths shown. Other lengths available to order.

Installation and materials compatibility

Info

The capacitor discharge (CD) process is suitable for attaching smaller diameter fasteners to thin sheet metal

applications. The weld cycle is completed in milliseconds meaning that weld can be achieved without generating

pronounced distortion or discolouration on the reverse side of the panel.

CD stud welding is a versatile single fastening process where threaded studs and unthreaded pins can be end

joined to a sheet metal application instantaneously.

CD Weld Studs and Pins are available in a range of thread sizes, diameters and lengths, manufactured from copper

coated steel, stainless steel, aluminium and brass and are suitable for use with compatible panel materials as thin

as 0.5mm. CD Weld studs and pins require appropriate stud welding equipment for attachment.

CAPACITOR DISCHARGE

(CD) WELD STUDS & PINS