Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Cage Nuts

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

SERVICES & SUPPORT

Clinch Nuts

Flush Nuts

Blind Nuts

Miniature Nuts

Nyloc Nuts

Locking Nuts

Floating Nuts

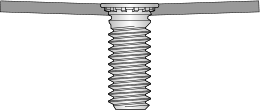

Flush Head Studs

Flush Head Studs for

Stainless Steel

Reduced Flush Head Studs

Thin Panel Non-Flush Studs

High Strength Studs

Thin Panel High Strength

Studs

Flush Head Pins

Flush Head Tapered Pins

Concealed Head Studs

Through & Blind Standoffs

Grounding Standoffs

Thin Panel Standoffs

Quick Release Standoffs

Keylock Standoffs

Concealed Head Standoffs

Flush Panel Screw Assembly

Panel Fasteners

Phillips Head Panel Fasteners

Low-Profile Panel Fasteners

Plunger Assembly

Self-Clinching fastener

Do’s and Don’ts

Self-Clinching fastener

problem solving guides

Self-Clinch in harder panels

NORTHERN PRECISION LIMITED

Specialist Fasteners

+44 (0) 1302 836010

sales@npfasteners.com

Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and approved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict Minerals Policy

Environmental Policy

Opening Hours

Mon - Thu

08:00 - 17:00

Fridays

08:00 - 16:30

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

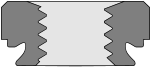

Fastener is not

fully seated

Problem

Poor performance. Part falls out of panel.

Cause

The fastener is not installed fully. You must ensure that the fastener is installed so

that no knurling is visible or the head is flush with the panel.

Solution

Apply more force and or increase the length of stroke on the press so that the

fastener is fully installed. The shoulder of the fastener should be in contact with

the panel and the knurling should not be visible.

Fastener is not

installed squarely

Problem

Poor performance. Part falls out of panel.

Cause

The punch and anvil faces are not and parallel or the panel was not held

perpendicular to the anvil and punch during installation.

Solution

Make sure that panels are supported and held perpendicular to the punch and

anvil. Punch and anvil faces must be parallel to each other.

Large gap

Problem

Poor performance. Fastener installs off centre.

Fastener located incorrectly

in hole resulting in side of

hole shearing as fastener is

installed. Limited holding

power in pane.

Cause

The hole is bigger than specification.

Solution

Make sure the hole is within specified tolerance. Ensure that the fastener is located

squarely in the hole before applying pressure.

Problem

Tight Threads. Fastener cracked after installation.

Shank protrudes through

bottom of panel and is

deformed by anvil.

Shank is cracked and

threads are tight.

Fastener squashed

and bulging sides

Fastener will

not fully seat

Cause

If you try to install a self-clinching fastener with the wrong shank length for the

panel, as the shank bottoms out on the anvil it will deform and crack.

Solution

You must use a part that is suitable for the panel thickness or ensure that the

panel meets the minimum panel thickness requirement for the specific fastener.

Problem

Poor performance. Part falls out of panel.

Hole has been countersunk

to deburr the hole.

Cause

Countersinking or chamfering removes material which is required during the

clinching process. There will not be enough material left to displace and fully fill the

clinch feature.

Solution

Do not remove any material by countersinking or chamfering the hole. The

shoulder of the hole should be square. It is always preferable to install the fastener

from the punch side of the panel.

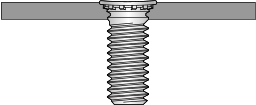

Anvil

Punch

Cupped head

Punch is too narrow

Problem

After installation the head of the stud, pin or

standoff is cupped and does not sit flush with the

surface of the panel.

Cause

The punch diameter is too small.

Solution

Use a punch with the correct diameter.

The punch should be wider than the head of the

fastener and ideally be the same diameter as the

anvil to avoid panel distortion.

Anvil

Flat Punch

Material is displaced

into the anvil instead of

fully filling the clinch

feature because the

anvil hole is too large.

Problem

Torque-out or push-out performance of fastener

is poor.

Cause

Anvil hole diameter is too large and is allowing

material to flow into anvil instead of the clinch

feature, or incorrect chamfered anvil is being

used.

Solution

Use an anvil with the correct diameter hole. Only

use a chamfered anvil where appropriate.

Anvil

Punch

Problem

Panel distorts when trying to install clinch studs in

thinner panels.

Cause

No chamfer on anvil. In thinner panels a chamfer

is required to accommodate the amount of

material that is displaced during installation.

Solution

Use the correct anvil type for the fastener and

panel thickness.

When installing our self-clinching fasteners, providing all technical requirements are met and installation

instructions are followed, you shouldn’t have any issues.

There are so many permutations of fastener type, size, panel material characteristics, hole preparation,

installation and tooling configuration that it is impossible to cover absolutely everything here. This is the

reason we state that the performance figures given for our fasteners are offered as guidance only.

Below are some of the most common issues encountered when installing self-clinching fasteners, along

with the cause and solution to ensure a successful installation an optimal performance.

If you are experiencing problems beyond the scope of this guide, please call our sales team for assistance.

Problem

Tight threads, poor performance. Part falls out of panel.

Cause

The panel is above the recommended hardness limit for the fastener.

Solution

For correct installation, self-clinching fasteners need to be harder than the panel

material they are being installed into. You must pay attention to the maximum

panel hardness limitation for the specific fastener type you are installing.

Fastener deformed,

bulging sides and tight

threads. Limited

displacement

of panel material.

A guide of Do’s and Don’ts when installing self-clinching fasteners can be found here.

Installing self-clinching fasteners in harder panel materials.

SELF-CLINCHING FASTENERS

SOLUTIONS TO COMMON PROBLEMS