Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Cage Nuts

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

SERVICES & SUPPORT

Clinch Nuts

Flush Nuts

Blind Nuts

Miniature Nuts

Nyloc Nuts

Locking Nuts

Floating Nuts

Flush Head Studs

Flush Head Studs for

Stainless Steel

Reduced Flush Head Studs

Thin Panel Non-Flush Studs

High Strength Studs

Thin Panel High Strength

Studs

Flush Head Pins

Flush Head Tapered Pins

Concealed Head Studs

Through & Blind Standoffs

Grounding Standoffs

Thin Panel Standoffs

Quick Release Standoffs

Keylock Standoffs

Concealed Head Standoffs

Flush Panel Screw Assembly

Panel Fasteners

Phillips Head Panel Fasteners

Low-Profile Panel Fasteners

Plunger Assembly

Self-Clinching fastener

Do’s and Don’ts

Self-Clinching fastener

problem solving guides

Self-Clinch in harder panels

NORTHERN PRECISION LIMITED

Specialist Fasteners

+44 (0) 1302 836010

sales@npfasteners.com

Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and approved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict Minerals Policy

Environmental Policy

Opening Hours

Mon - Thu

08:00 - 17:00

Fridays

08:00 - 16:30

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

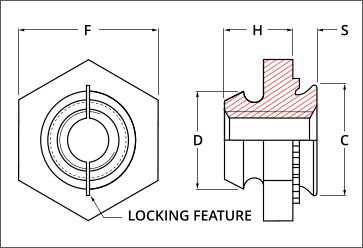

Dimensional

Material & Finish

Zinc Plated Carbon Steel + Dry Film Lubricant coating (MD) parts are suitable for

installation in ductile panels with a maximum recommended hardness of 70 HRB.

300 Series Stainless Steel + Dry Film Lubricant coating (A2) parts are suitable for

installation in ductile panels with a maximum recommended hardness of 70 HRB.

Aluminium (AL) arts are suitable for installation in ductile panels with a maximum

recommended hardness of 50 HRB.

Part Number Examples

Part number is made up as follows:

(Type)-(Thread)-(Material code)-(Material/Finish code)

For example:

LCN-M3-1-MD (Locking Nut-M3-1.0mm min sheet thickness-zinc plated carbon steel plus

Dry Film Lubricant coating)

LCN-M4-2-A2 (Locking Nut-M4-1.4mm min sheet thickness-stainless steel plus Dry Film

Lubricant coating)

LCN-M5-2-AL (Locking Nut-M5-1.4mm min sheet thickness-aluminium)

Info

Self-Clinching Locking Nuts provide strong female prevailing torque locking threads in panels that are too thin to be

conventionally tapped.

Utilising a special proven clinch feature, this fastener has excellent torque-out and push-out characteristics whilst

providing a flush finish on the underside of the panel.

Featuring two symmetrically threaded jaws and a dry film lubricant coating to provide a strong and effective

prevailing torque locking action to minimise the risk of loosening when under heavy usage.

Like all self clinching fasteners they are installed using a parallel squeezing action, so require access to both sides of

the panel.

Locking Nuts are available in various thread sizes, manufactured from zinc plated steel and 300 series stainless

steel plus a dry film lubricant coating and are suitable for installation in ductile steel and aluminium panels with a

recommended maximum hardness of 70 HRB and aluminium with no dry film lubricant which are suitable for

installation in ductile aluminium panels with a recommended maximum hardness of 50 HRB.

Thread

Size

Material

code

S

Max.

Hole size

+0.08 -0.0

C

Max.

D

Max.

Min sheet

thickness

Min .CL

to edge

of panel

1

1.0

0.97

2

1.4

1.38

4.73

4.85

4.75

4.0

M3 x 0.5

1

1.0

0.97

2

1.4

1.38

6.73

6.20

6.76

5.2

M4 x 0.7

1

1.0

0.97

2

1.4

1.38

7.90

7.75

7.92

5.6

M5 x 0.8

H

±0.40

3.43

4.45

5.21

Max. prevailing

locking torque

Nm (guideline)

0.56

1.70

2.00

F

Nom.

6.35

8.73

9.53

Type LCN

SELF-CLINCHING

LOCKING NUTS