Contact us

You can contact us using any

of the methods below.

Unit 3 Durham Lane

Armthorpe

Doncaster

South Yorkshire DN3 3FE

England

+44 (0)1302 836010

+44 (0)1302 831555

sales@npfasteners.com

All rights reserved

© Northern Precision Ltd.

NORTHERN PRECISION LTD

Accreditations

Northern Precision Ltd operate a quality management

system in accordance with ISO 9001.

The ISO 9001 standard is recognised worldwide and

you can be assured of the benefits of working with a

certified company knowing that our management

systems are constantly assessed and improved.

Regulatory

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

statement

Environmental Policy

Opening Hours

Mon - Fri 08:00 - 17:00

Registered in England & Wales

Company number 3275391

V.A.T Registration number

GB 684 1384 17

NORTHERN PRECISION LTD

Specialist Fasteners

for Sheet Metal

+44 (0) 1302 836010

+44 (0) 1302 831555

Tel:

Fax:

sales@npfasteners.com

Quality

Service

Reliability

Self-Clinching Fasteners

Broaching Fasteners

Arnold & Shinjo Fasteners

Rivet Bushes

Rivet Nuts

Weld Fasteners

Cage Nuts

Blind Rivets

Inserts for Plastics

Inserts for Stone, Solid

Materials, Composites &

Sandwich Panels

Crown-Nuts

Fast-Con

Installation Equipment

Turned & Cold Formed

special parts made to order

Bespoke fastener design &

development

Fastener & Application

testing

Technical support

ISO 9001

RoHS|WEEE Compliance

REACH Compliance

Conflict minerals

Environmental Policy

SERVICES & SUPPORT

Standard Rivets Dome Head

Standard Rivets Countersunk

Head

Standard Rivets Large Head

Multigrip Rivets Dome Head

Multigrip Rivets Countersunk

Head

Multigrip Rivets Large Head

Peel Rivets Domed Head

Peel Rivets Large Head

Sealed Rivets Dome Head

Sealed Rivets Countersunk

Head

Sealed Rivets Large Head

Grooved Rivets Dome Head

Installation Tools, Spares and

Servicing

Material & Finish

Aluminium Body (Al Mg 3.5) / Steel+Zinc Mandrel

(AL/ST)

Aluminium Body (Al Mg 3.5) / Stainless (304) Mandrel

(AL/A2)

Aluminium Body (Al Mg Si) / Aluminium Mandrel (AL/AL)

Steel+Zinc Body / Steel+Zinc Mandrel (ST/ST)

Stainless Body (304) / Stainless (304) Mandrel (A2/A2)

*Shear & Tensile performance is based on Aluminium/Steel.

For performance figures for other materials please contact us.

Part Number Examples

Part number is made up as follows:

(Type)-(Size Code)-(Material & Finish Code)-(Optional

Colour)

For example:

RSTNDLF-3210-AL/ST (Standard Large Head Rivet-

3.2mm body to suit 5-7mm grip-aluminium body/zinc

plated steel mandrel)

RSTNDLF-4812-A2/A2 (Standard Large Head Rivet-

4.8mm body to suit 6-8mm grip-304 stainless steel

body/304 stainless steel mandrel)

Downloadable Data Sheet

Back

Dimensional

Shear

(N)*

Tensile

(N)*

Grip Range

L

Nom.

750

1100

0.5 - 3.5

3.5 - 5.0

5.0 - 7.0

7.0 - 9.0

9.0 - 13.0

6

8

10

12

16

1250

1800

3.0 - 5.0

5.0 - 6.5

6.5 - 8.5

8.5 - 10.5

10.5 - 12.5

12.5 - 14.5

14.5 - 16.5

8

10

12

14

16

18

20

1850

2600

4.5 - 6.0

6.0 - 8.0

8.0 - 10.0

10.0 - 12.0

12.0 - 14.0

14.0 - 17.0

17.0 - 20.0

20.0 - 23.0

23.0 - 25.0

25.0 - 27.0

27.0 - 30.0

30.0 - 35.0

35.0 - 40.0

40.0 - 45.0

10

12

14

16

18

21

24

27

30

32

35

40

45

50

2150

3100

3.0 - 4.5

4.5 - 6.0

6.0 - 8.0

8.0 - 10.0

10.0 - 12.0

12.0 - 14.0

14.0 - 16.0

16.0 - 21.0

21.0 - 25.0

8

10

12

14

16

18

20

25

30

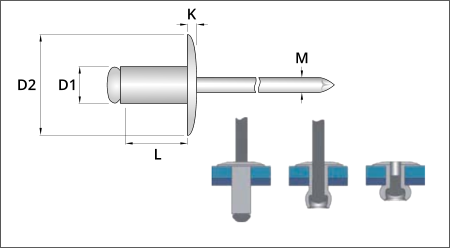

D1

3.2

4.0

4.8

5.0

K

1.10

1.40

1.80

1.60

Hole

Size

3.30

4.10

4.90

5.10

D2

9.50

12.00

14.00

11.0

M

1.80

2.20

2.65

2.65

Size

Code

3206

3208

3210

3212

3216

4008

4010

4012

4014

4016

4018

4020

4810

4812

4814

4816

4818

4821

4824

4827

4830

4832

4835

4840

4845

4850

5008

5010

5012

5014

5016

5018

5020

5025

5030

1850

2600

4.5 - 6.0

6.0 - 8.0

8.0 - 10.0

10.0 - 12.0

12.0 - 14.0

14.0 - 17.0

17.0 - 20.0

20.0 - 23.0

23.0 - 25.0

25.0 - 30.0

10

12

14

16

18

21

24

27

30

35

4.8

1.80

4.90

16.00

2.65

(16)4810

(16)4812

(16)4814

(16)4816

(16)4818

(16)4821

(16)4824

(16)4827

(16)4830

(16)4835

2150

3100

3.0 - 4.5

4.5 - 6.0

6.0 - 8.0

8.0 - 10.0

10.0 - 12.0

12.0 - 14.0

14.0 - 16.0

16.0 - 21.0

21.0 - 25.0

8

10

12

14

16

18

20

25

30

5.0

1.80

5.10

14.0

2.65

(14)5008

(14)5010

(14)5012

(14)5014

(14)5016

(14)5018

(14)5020

(14)5025

(14)5030

All dimensions are in mm

Info

Blind Rivets (often referred to as breakstem rivets) allow two or more similar or different materials to be joined

together from one side of the application.

Available in a combination of diameters, grip-ranges and materials, standard large head rivets are a highly versatile

and cost effective, industry proven joining method. This head style provides double the bearing area compared to

dome head rivets, they are designed for applications where a soft or brittle material is assembled to a rigid support

material.

Installation is simple, with tooling ranging from cheap pistol-grip style guns to air-powered placement equipment

suitable for production line work.

Applications include, automotive, aerospace, furniture, restoration, sheet metal fabrication etc.

TYPE RSTNDLF

STANDARD RIVETS

LARGE HEAD